Les pros du Backflow

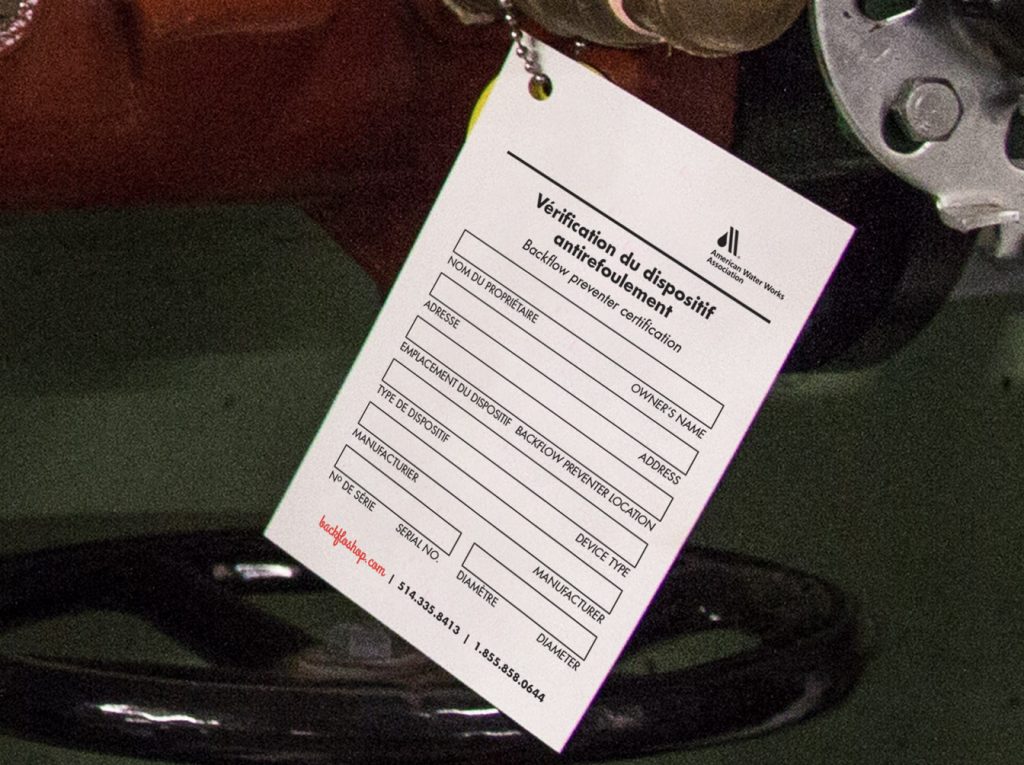

Nous sommes les experts en vente, entretien et réparation de manomètres différentiels et de dispositifs antirefoulement.

SAVOIR FAIRE À PRIX COMPÉTITIFS

Depuis 2006, nos experts aident les vérificateurs de dispositifs antirefoulement, les entrepreneurs en plomberie, les propriétaires et les gestionnaires de bâtiments ainsi que le personnel d’entretien à sélectionner et à installer les dispositifs antirefoulement conformes aux lois et codes en vigueur.

Nous calibrons tout type de manomètre différentiel dans un délai rapide et à prix compétitif.

Calibration annuelle des résultats précis pour un travail de pro!

PRODUITS

Manomètre différentiel

BLOGUE

Isolation thermique amovible ; une solution pratique et rentable

Lorsqu’il s’agit d’isoler les tuyaux et les canalisations, le calorifugeage est une technique essentielle pour minimiser les déperditions thermiques et assurer une meilleure efficacité énergétique

Pourquoi calibrer son manomètre annuellement ?

Pourquoi faut-il calibrer son manomètre différentiel annuellement ? Les manomètres différentiels sont utilisés pour la certification annuelle obligatoire des dispositifs antirefoulement. Pourtant, plusieurs propriétaires ne

5 erreurs lors de l’installation d’un dispositif antirefoulement

Les 5 erreurs les plus fréquentes lors de l’installation d’un dispositif antirefoulement (DAr) : De nombreux problèmes peuvent résulter de l’installation inadéquate d’un dispositif antirefoulement, notamment

Eau potable et contamination au plomb

Des moyens simples pour prévenir la contamination – Santé Canada limite la teneur en plomb dans l’eau potable à 10 parties par milliard dans un échantillon