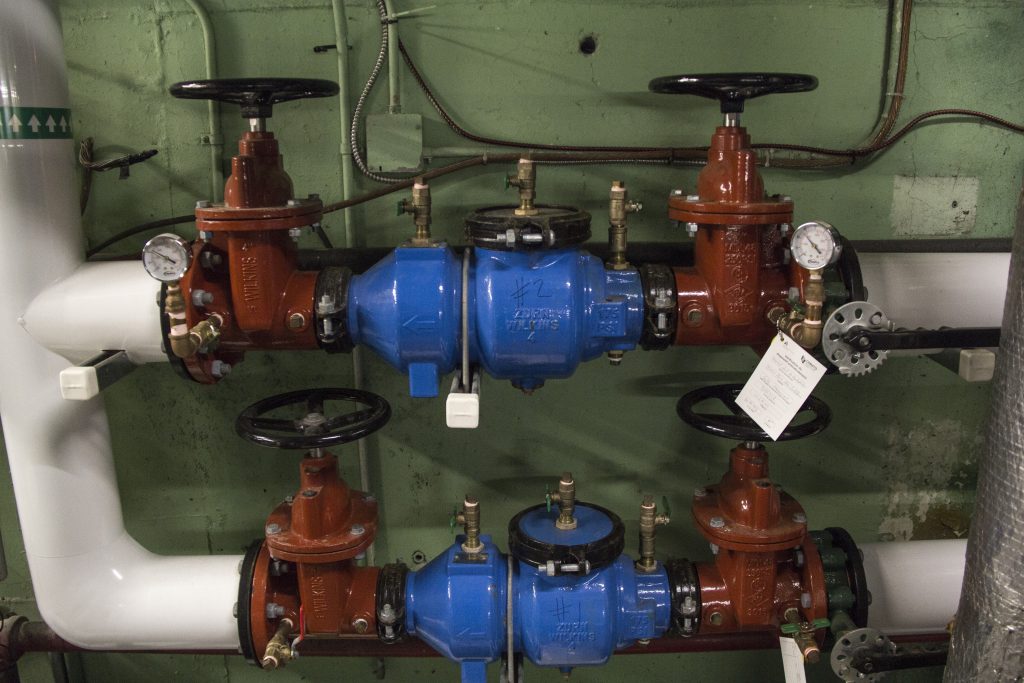

DAr failure might occur anytime. Indeed, backflow prevention devices (DAr) play a crucial role in preventing the contamination of water networks by undesirable substances. Although they are essential for public health and environmental protection, these devices are often subject to breakage. A breakage is reflected by a failure of the annual certification or by a failure of the waterproofing. That said, these failures therefore expose our communities to significant health risks. But why are these dysfunctions so widespread? This article takes a detailed look at the four main causes of ADR failure in order to understand and prevent these problems.

Temperature : Main cause of DAr failure

Extreme temperatures are one of the main causes of ADR failure. The mechanical components of ARs, often made from materials such as plastic or rubber, can expand or contract depending on temperature changes. These expansions and contractions can lead to cracks or warping, compromising the seal of the check valves within the devices. Additionally, prolonged exposure to extreme temperatures, whether hot or cold, can accelerate the aging of materials. This prolonged exposure will have the effect of reducing their effectiveness and durability. That said, it is crucial to choose ADRs adapted to specific climatic conditions and, if possible, to protect them against excessive temperature fluctuations.3

Minerals in the city’s water

Mineral that are dissolved in city water can also be a significant source of DAr dysfunction. When water is stagnant for a long period of time, substances such as calcium and magnesium can build up on the internal components of the devices and form limescale deposits. These deposits can obstruct the closing and opening mechanisms of the valves, thus preventing the DAr from functioning correctly. Over time, this mineral buildup can damage components, requiring frequent maintenance and sometimes even replacement of devices.1

Debris in the water

The presence of debris such as rocks, pieces of rust, grease from welds and other solid particles in the water is another common cause of ADR failure. In fact, this debris often comes from work carried out on the water network. Additionally, a lack of care when installing ADRs can allow unwanted particles to enter the system. Consequently, by lodging in the moving components of the devices, this debris can hinder the proper functioning of the DARs; the valves can be stuck in the open or closed position, compromising the safety of the systems. To reduce the risk of malfunctions linked to debris, the installation of sieves or filters upstream of the DArs proves to be an effective solution.

Additionally, these filtration tools capture particles before they reach the DAr. However, it is essential to empty these tools regularly to avoid excessive accumulation of debris, which could in turn impair the proper functioning of the systems.2

Pressure fluctuations

Pressure fluctuations in the water supply network can lead to premature failure of DAr. Indeed, rapid and frequent variations in pressure, caused by changes in flow rate, place heavy demands on mechanical components, such as seals and valves. This constant wear can cause leaks or ruptures, thus compromising the sealing and proper functioning of the devices. This problem is particularly common in large industrial processes where water flow rates vary significantly.3

What to remember?

Factors such as temperature extremes, dissolved minerals, debris in the water, and pressure fluctuations can cause frequent failures. So, to prevent these problems, choose suitable DAr and protect them against fluctuations.

Article by Marcu Badan, published August 29th, 2024, extracted from Darspec.

Another interesting article: Removable thermal insulation; a practical and cost-effective solution

Références :

- Plumbing Rocket. (2020, 25 novembre). Calcium Build-up in Your Drains and Pipes ? Here’s How To Fix It | Rocket Plumbing. Best Plumber in Chicago & ; Lombard, IL | Rocket Plumbing. https://rocketplumbingnow.com/blog/calcium-build-up-in-your-drains-and-pipes-heres-how-to-fix-it/

- Direct Material. (2019, 18 avril). Y-Strainers : Keeping Things Clean. Wholesale Industrial Parts | Valves & ; Gauges. https://www.directmaterial.com/y-strainers-keeping-things-clean

- Trouble Shooters. (s. d.). Wondering why did your backflow device test failed ? Trouble Shooters Plumbing. https://torontoplumbers.com/why-did-my-backflow-device-test-fail/